A drum spill pallet is a crucial safety device designed to contain and manage spills or leaks from drums or barrels. These pallets are commonly used in industrial, commercial, and environmental settings where hazardous materials, chemicals, or liquids are stored and handled. The primary purpose of a drum spill pallet is to prevent spills from contaminating the surrounding environment, ensuring safety and regulatory compliance.

Key Features:

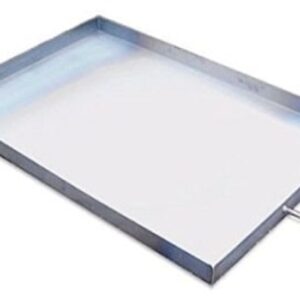

- Durable Construction: Made from heavy-duty materials such as polyethylene, steel, or a combination of both, drum spill pallets are built to withstand harsh conditions and resist damage from chemicals, corrosives, and physical impacts.

- Containment Capacity: Designed with a sump or containment area that can hold the full volume of liquid from one or more drums in the event of a spill. This capacity helps to prevent environmental contamination and ensures that any leaks or spills are contained effectively.

- Modular and Versatile: Available in various configurations to accommodate different sizes and numbers of drums or barrels. Some models feature modular designs that allow for expansion or customization based on specific needs.

- Easy to Clean: Constructed from materials that are resistant to chemical damage and easy to clean, ensuring that the spill pallet remains functional and hygienic after use.

- Built-In Drainage: Many drum spill pallets include built-in drainage systems or removable grates that facilitate the easy removal of spilled liquids and make it easier to maintain the pallet.

- Non-Slip Surface: Often designed with non-slip surfaces or grates to provide stability and prevent drums from shifting or tipping, reducing the risk of accidents during handling.

- Compliance with Regulations: Meets or exceeds environmental and safety regulations, such as those set by OSHA, EPA, or local regulations, ensuring that your facility remains compliant with spill containment standards.

Applications:

- Industrial Facilities: Used in manufacturing plants, warehouses, and chemical processing facilities to manage and contain spills from drums or barrels of hazardous or non-hazardous liquids.

- Chemical Storage: Applied in facilities where chemicals are stored in drums to ensure that any leaks or spills are contained and managed effectively.

- Environmental Protection: Utilized in areas where environmental protection is a concern, helping to prevent contamination of soil and water from hazardous spills.

Benefits:

- Enhanced Safety: Provides a secure method for containing spills, reducing the risk of accidents, environmental contamination, and safety hazards.

- Regulatory Compliance: Supports adherence to environmental and safety regulations, helping to ensure that your facility meets legal requirements for spill containment.

- Versatile and Durable: Suitable for a wide range of applications and built to withstand harsh conditions, making it a reliable choice for various industrial and commercial environments.

Reviews

There are no reviews yet.