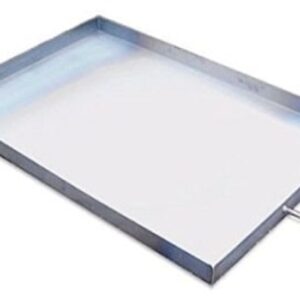

A covered spill pallet is an advanced spill containment solution designed to manage and contain spills or leaks from drums, barrels, or other containers while offering additional protection from environmental elements. The cover ensures that stored liquids are safeguarded against rain, dust, and other contaminants, enhancing the effectiveness of the spill containment system and maintaining compliance with safety and environmental regulations.

Key Features:

- Durable Construction: Built from high-quality, impact-resistant materials such as polyethylene, steel, or a combination of both, the covered spill pallet is designed to withstand harsh conditions, including exposure to chemicals, weather elements, and physical impacts.

- Containment Capacity: Includes a sump or containment area that can hold the full volume of liquid from one or more drums in the event of a spill. The pallet’s capacity ensures that any leaks or spills are contained effectively, preventing environmental contamination.

- Protective Cover: Features a robust cover that shields the stored drums or barrels from environmental elements such as rain, snow, dust, and UV rays. The cover helps to keep the stored liquids clean and reduces the risk of contamination.

- Ventilation and Access: Many covered spill pallets are equipped with ventilation openings or removable panels to allow for easy access to the drums or barrels while maintaining containment. The cover design often includes access points or doors for convenient handling and inspection.

- Modular and Versatile: Available in various sizes and configurations to accommodate different numbers and sizes of drums or barrels. Some models offer modular designs that allow for expansion or customization based on specific needs.

- Easy to Clean: Constructed from materials that are resistant to chemical damage and easy to clean, ensuring that the spill pallet remains functional and hygienic after use.

- Compliance with Regulations: Meets or exceeds environmental and safety regulations, such as those set by OSHA, EPA, or local regulations, ensuring that your facility remains compliant with spill containment standards.

Applications:

- Industrial Facilities: Used in manufacturing plants, warehouses, and chemical processing facilities to manage and contain spills from drums or barrels, while also protecting the stored liquids from environmental contaminants.

- Chemical Storage: Applied in facilities where chemicals are stored in drums to ensure effective spill containment and protection from weather elements.

- Outdoor Storage Areas: Ideal for outdoor environments where protection from rain, snow, and dust is crucial for maintaining the integrity of the stored liquids.

Benefits:

- Enhanced Protection: Provides a secure method for containing spills and protecting stored liquids from environmental elements, reducing the risk of contamination and ensuring safety.

- Regulatory Compliance: Supports adherence to environmental and safety regulations, helping to ensure that your facility meets legal requirements for spill containment.

- Versatile and Durable: Suitable for a wide range of applications and built to withstand harsh conditions, making it a reliable choice for various industrial and commercial environments.

Reviews

There are no reviews yet.