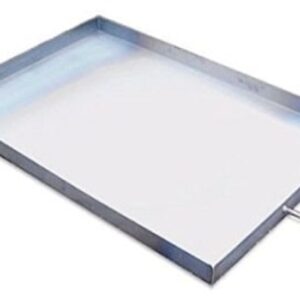

A GI (Galvanized Iron) steel spill pallet is a robust and durable containment solution designed to manage and contain spills from drums, barrels, or other containers in industrial and commercial environments. Constructed from galvanized steel, these pallets offer superior resistance to corrosion and harsh environmental conditions, making them ideal for use in settings where chemicals or hazardous materials are stored and handled.

Key Features:

- Galvanized Steel Construction: The pallet is made from steel coated with a layer of zinc through the galvanization process. This coating provides excellent resistance to rust, corrosion, and chemical damage, ensuring long-term durability even in challenging environments.

- High Load Capacity: Designed to support heavy loads, including multiple drums or barrels. The robust steel construction allows the pallet to handle significant weight without compromising structural integrity.

- Containment Sump: Equipped with a sump or containment area that can capture and hold the full volume of liquid from one or more drums in the event of a spill. This helps to prevent spills from contaminating the surrounding environment and facilitates easy cleanup.

- Mesh or Grated Surface: Often features a mesh or grated surface to provide stability for the stored drums or barrels while allowing any spilled liquids to drain into the containment area. This design helps to keep the stored items secure and makes it easier to manage spills.

- Drainage Options: Some models include drainage ports or removable grates to facilitate the easy removal of spilled liquids and to keep the pallet clean and functional.

- Durable and Easy to Clean: The galvanized steel surface is resistant to chemical damage and easy to clean, ensuring that the pallet remains in good condition and hygienic after use.

- Compliance with Regulations: Meets or exceeds environmental and safety regulations, such as those set by OSHA, EPA, or local regulations, ensuring that your facility remains compliant with spill containment standards.

Applications:

- Industrial Facilities: Used in manufacturing plants, chemical processing facilities, and warehouses to manage and contain spills from drums or barrels of hazardous or non-hazardous liquids.

- Chemical Storage: Applied in facilities where chemicals are stored in drums to ensure effective spill containment and to protect against environmental contamination.

- Maintenance and Safety Areas: Ideal for areas where maintenance is performed on equipment containing fluids, to prevent spills and leaks from affecting the environment.

Benefits:

- Enhanced Protection: Provides a reliable method for containing spills and preventing environmental contamination, reducing the risk of accidents and regulatory violations.

- Long-Lasting Durability: The galvanized steel construction offers superior resistance to rust and corrosion, ensuring a long service life even in harsh conditions.

- Versatile and Functional: Suitable for a variety of applications and designed to handle heavy loads, making it a flexible and dependable choice for various industrial and commercial needs.

Reviews

There are no reviews yet.