Hydraulic Tube & Pipe Clamps – Secure, Vibration-Resistant Mounting Solutions

Anchor your hydraulic systems with precision using our hydraulic tube and pipe clamps, engineered for secure, vibration-dampening support across a wide range of industrial applications. Designed in compliance with DIN 3015 standards, these clamps ensure reliable performance, reduced noise, and long-term durability for both tubing and piping installations.

✅ Key Features

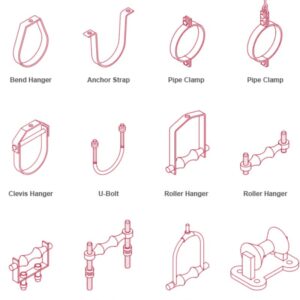

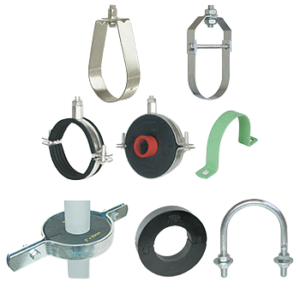

- Single, twin, and heavy-duty clamp designs for varied pressure and load requirements

- Clamp bodies in polypropylene, polyamide, or aluminum for chemical and thermal resistance

- Zinc-plated and stainless steel hardware for corrosion protection in harsh environments

- Supports pipe and tube diameters from 6 mm to 450 mm

- Quick-install components including weld plates, cover plates, and bolts

🏭 Applications

Ideal for hydraulic machinery, process piping, mobile equipment, and marine systems, our clamps provide structured support for both thin-walled tubes and thick-walled pipes—minimizing vibration, wear, and system fatigue.

Reviews

There are no reviews yet.