Fasteners are hardware devices used to join, secure, or attach two or more components together. They come in a wide range of types, sizes, and materials, each designed for specific applications and requirements. Fasteners are crucial in construction, manufacturing, automotive, aerospace, and many other industries, providing structural integrity and functionality to assembled products and structures.

Key Features:

- Variety of Types: Fasteners include screws, bolts, nuts, washers, rivets, pins, and clips, each serving different purposes. The choice of fastener depends on the materials being joined and the desired strength and durability.

- Material Options: Fasteners are made from various materials, including steel, stainless steel, aluminum, brass, plastic, and others. Material choice affects strength, corrosion resistance, and suitability for different environments.

- Size and Threading: Fasteners come in numerous sizes and threading options to accommodate various applications. Threads can be coarse or fine, and sizes range from very small to large, depending on the needs of the project.

- Strength and Durability: The strength and durability of a fastener depend on its material and design. High-strength fasteners are used in critical applications where reliability and safety are paramount.

- Ease of Installation: Many fasteners are designed for easy installation and removal using common tools, such as screwdrivers, wrenches, or drills. Some fasteners are designed for specialized tools or automated machinery.

- Corrosion Resistance: Some fasteners are coated or treated to resist corrosion and wear, making them suitable for use in harsh environments or outdoor applications.

Types of Fasteners:

- Screws: Designed to be driven into materials to create a secure connection. Common types include machine screws, wood screws, self-tapping screws, and sheet metal screws.

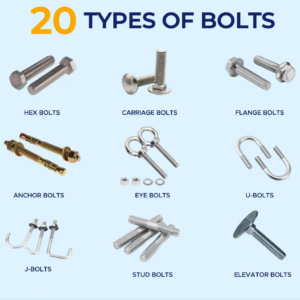

- Bolts: Used with nuts and washers to secure components together. Types include hex bolts, carriage bolts, and eye bolts, each serving specific functions.

- Nuts: Used in conjunction with bolts to fasten components. They come in various shapes and sizes, including hex nuts, lock nuts, and wing nuts.

- Washers: Placed between the fastener head and the surface to distribute load and prevent damage. Types include flat washers, lock washers, and split washers.

- Rivets: Permanent fasteners used to join components by deforming the rivet material. Types include solid rivets, blind rivets, and pop rivets.

- Pins: Fasteners used to secure components in place or align them. Types include cotter pins, dowel pins, and clevis pins.

- Clips and Clamps: Used to hold components together or in place temporarily. Examples include spring clips, hose clamps, and cable clamps.

- Anchors: Fasteners used to secure objects to walls or other surfaces. Types include wall anchors, concrete anchors, and expansion anchors.

Applications:

- Construction: Fasteners are used to join structural elements, such as beams, columns, and studs, as well as for installing fixtures and fittings.

- Manufacturing: Used in assembly processes for various products, including machinery, electronics, and consumer goods.

- Automotive: Essential in vehicle assembly and repair, securing parts such as engines, chassis, and interior components.

- Aerospace: Used in aircraft construction and maintenance, where high strength and precision are critical.

- DIY and Home Improvement: Commonly used in home projects for assembling furniture, mounting fixtures, and making repairs.

Benefits:

- Secure Connections: Provide strong and reliable connections between components, ensuring structural integrity and functionality.

- Versatility: Available in a wide range of types, sizes, and materials to suit various applications and requirements.

- Ease of Use: Designed for straightforward installation and removal, making them practical for both professional and DIY projects.

- Customization: Can be tailored to specific needs with various threading, coating, and material options.

Reviews

There are no reviews yet.