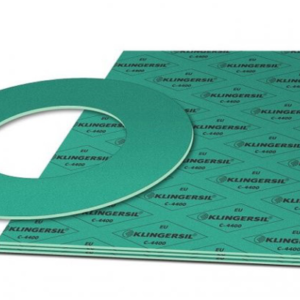

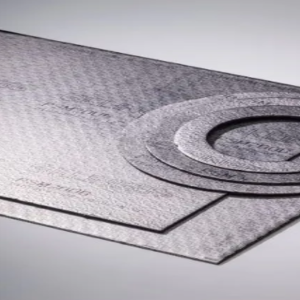

Non-Metallic Gaskets are sealing components made from materials other than metals, designed to create a reliable seal between flanged connections or other joint surfaces. These gaskets are typically used in applications where flexibility, chemical resistance, and temperature stability are required, but where metal gaskets might not be suitable.

Key Features:

- Material Variety: Made from materials such as rubber, silicone, PTFE (Teflon), graphite, and compressed fiber. Each material offers unique properties suited for specific applications.

- Flexibility and Compressibility: Non-metallic gaskets can compress and conform to irregular surfaces, ensuring a tight seal even in uneven or misaligned joints.

- Temperature and Pressure Resistance: Available in materials that can handle a range of temperatures and pressures, though typically less extreme than those handled by metallic gaskets.

- Chemical Resistance: Many non-metallic gaskets provide good resistance to various chemicals, including acids, bases, and solvents, depending on the material used.

- Ease of Installation: Generally lighter and easier to cut or shape, making them simpler to install and replace compared to metallic gaskets.

Applications:

- Industrial Equipment: Used in machinery, pumps, and flanges where a flexible and compressible seal is needed to handle vibration and thermal expansion.

- Automotive: Applied in engine components, gaskets for carburetors, and exhaust systems where high flexibility and temperature resistance are required.

- HVAC Systems: Employed in heating, ventilation, and air conditioning systems for sealing purposes where flexibility and thermal stability are important.

- Chemical Processing: Utilized in environments with corrosive chemicals where material-specific resistance is required, such as PTFE or graphite gaskets.

- Water and Wastewater Treatment: Used in water treatment facilities and other applications where a tight seal is necessary to prevent leaks and maintain system integrity.

Benefits:

- Versatility: Available in various materials to meet different sealing requirements, including flexibility, chemical resistance, and temperature tolerance.

- Effective Sealing: Provides reliable seals that conform to irregular surfaces, reducing the risk of leaks and ensuring proper operation.

- Ease of Maintenance: Generally easier to install and replace compared to metallic gaskets, facilitating maintenance and repairs.

- Cost-Effective: Often less expensive than metallic gaskets, making them a cost-effective choice for many applications.

Reviews

There are no reviews yet.