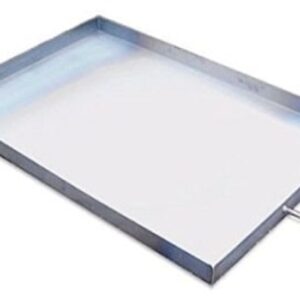

Plastic spill and drip trays are essential tools designed to manage and contain spills, leaks, or drips from various containers such as drums, barrels, and equipment. Made from high-quality plastic materials, these trays are ideal for preventing environmental contamination, ensuring workplace safety, and maintaining cleanliness in industrial, commercial, and laboratory settings.

Key Features:

- Durable Plastic Construction: Made from heavy-duty plastics like polyethylene or polypropylene, these trays are resistant to impact, chemicals, and UV exposure. This ensures they remain effective and durable even under harsh conditions.

- Spill Containment: Designed with a containment area that can hold the volume of liquid from a container in the event of a spill. This feature prevents spills from reaching the floor or surrounding environment, minimizing contamination and making cleanup easier.

- Drip Collection: Many trays include features such as raised edges or built-in grates to catch and contain drips from equipment or containers. This helps to maintain a clean and safe workspace by collecting drips and preventing them from spreading.

- Lightweight and Portable: Plastic trays are generally lightweight and easy to handle, making them convenient to move and position as needed. This portability is beneficial for changing work environments or temporary setups.

- Easy to Clean: The smooth plastic surface is easy to clean and maintain, which helps in managing spills and drips effectively. Many trays can be washed down with standard cleaning solutions and water.

- Various Sizes and Shapes: Available in a range of sizes and shapes to suit different needs and applications. Whether you need a small tray for a single container or a larger one for multiple drums, there is likely a suitable option available.

- Non-Slip Base: Some models feature a non-slip base or feet to prevent the tray from moving or shifting, ensuring stability and safety during use.

- Compliance with Safety Standards: Often designed to meet or exceed relevant safety and environmental regulations, ensuring that they contribute to a safe and compliant work environment.

Applications:

- Industrial Facilities: Used to manage spills and drips in manufacturing plants, warehouses, and chemical processing facilities, protecting floors and equipment from damage.

- Laboratories: Applied in labs to contain spills from chemicals and prevent contamination in sensitive areas.

- Commercial Settings: Ideal for use in retail and service environments where equipment may leak or drip, helping to maintain a clean and safe workspace.

- Maintenance Areas: Utilized in areas where equipment is serviced or repaired to catch and contain any drips or leaks from fluids.

Benefits:

- Enhanced Safety: Provides a reliable method for containing spills and drips, reducing the risk of slips, falls, and environmental contamination.

- Convenient and Practical: Lightweight and easy to move, making them suitable for various applications and work environments.

- Cost-Effective: Offers a cost-effective solution for managing spills and drips, helping to protect valuable equipment and maintain a clean workspace.

Reviews

There are no reviews yet.