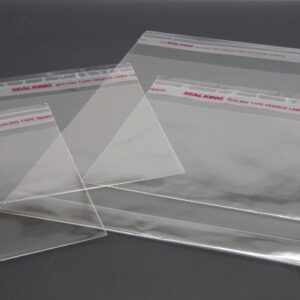

PLE, or Polyethylene Laminated Film, is a type of flexible packaging material commonly used in various industries for its durability and protective properties. This material is created by laminating layers of polyethylene with other films to enhance its strength, barrier properties, and functionality. It is widely used for packaging, wrapping, and protective applications due to its versatility and performance characteristics.

Key Features:

- Layered Construction: PLE is made by laminating multiple layers of polyethylene with other films such as aluminum or polyester. This layered construction improves its barrier properties and overall strength.

- Moisture Resistance: The polyethylene layer provides excellent resistance to moisture and water, making PLE suitable for protecting products from humidity and liquid exposure.

- Durability: PLE is known for its high tensile strength and resistance to tearing and puncturing. This durability ensures that it can withstand rough handling and protect contents during transit and storage.

- Clarity: Depending on the application, PLE can be produced with varying degrees of clarity. Transparent PLE allows for visibility of the packaged contents, while opaque versions provide additional privacy and protection.

- Flexibility: The film is highly flexible, allowing it to conform to various shapes and sizes of products. This flexibility makes it versatile for different packaging and wrapping needs.

- Barrier Properties: PLE can offer enhanced barrier properties against gases, odors, and UV light, depending on the specific laminate configuration. This makes it effective for preserving the quality and freshness of food products and other sensitive items.

- Customizable: Available in different thicknesses, finishes, and sizes, PLE can be customized to meet specific packaging requirements and preferences.

Types of PLE:

- Standard PLE Film: Used for general packaging and wrapping applications. It provides basic protection and is suitable for a wide range of products.

- Barrier PLE Film: Features additional layers or coatings to enhance barrier properties against moisture, gases, and light. Ideal for packaging products that require extended shelf life or protection from environmental factors.

- Glossy PLE Film: Provides a shiny, reflective surface that enhances the appearance of packaged products. Often used for consumer goods and retail packaging.

- Matte PLE Film: Offers a non-reflective surface that can reduce glare and provide a more subtle appearance. Suitable for applications where a sleek, understated look is desired.

- Perforated PLE Film: Includes small perforations to allow for ventilation or controlled release of gases. Used in applications where breathability is required, such as for fresh produce packaging.

Applications:

- Packaging: Used for wrapping and sealing products to protect them from moisture, contaminants, and damage. Commonly used in food packaging, pharmaceuticals, and consumer goods.

- Protective Wrapping: Provides cushioning and protection for items during transit and storage, helping to prevent scratches, dents, and other forms of damage.

- Industrial: Employed in industrial settings for packaging components, machinery, and other products that require protection from environmental factors and physical damage.

- Retail: Used for consumer packaging, enhancing product presentation and providing essential protection during display and transportation.

Benefits:

- Effective Protection: Provides reliable protection against moisture, contaminants, and physical damage, ensuring the safety and integrity of packaged products.

- Versatility: Suitable for a wide range of applications, from food packaging to industrial use, with customizable options to meet specific needs.

- Durability: Offers high strength and resistance to tearing, puncturing, and other stresses, making it a robust packaging solution.

- Clarity and Aesthetics: Available in clear or opaque finishes, enhancing product visibility and presentation while providing functional protection.

Reviews

There are no reviews yet.