PP straps, or polypropylene straps, are versatile and durable strapping materials used for securing, bundling, and reinforcing various types of goods and packages. Made from polypropylene plastic, these straps offer a lightweight yet strong solution for a wide range of applications in industrial, commercial, and logistical settings.

Key Features:

- Durable Material: PP straps are made from polypropylene, a thermoplastic polymer known for its strength and flexibility. This material is resistant to abrasion, impacts, and environmental factors, ensuring reliable performance in various conditions.

- High Tensile Strength: Despite being lightweight, polypropylene straps offer high tensile strength, allowing them to securely hold and stabilize heavy and bulky items. This strength helps to prevent shifting and damage during storage and transportation.

- Flexibility and Elasticity: PP straps have good flexibility and elasticity, which allows them to conform to the shape of the items being secured. This feature helps to ensure a snug and secure fit, reducing the risk of shifting or movement.

- UV Resistance: Some polypropylene straps are treated to resist UV radiation, making them suitable for outdoor use where exposure to sunlight and weather conditions is a concern. This treatment helps to prolong the life of the straps.

- Corrosion and Chemical Resistance: Polypropylene straps are resistant to many chemicals and moisture, which prevents rusting and degradation even when exposed to harsh environments.

- Cost-Effective: Generally more affordable than metal or other types of strapping, PP straps offer a cost-effective solution for various strapping needs. They provide good performance at a lower price point.

- Easy to Handle and Apply: PP straps are lightweight and easy to handle. They can be applied using manual or automatic strapping machines, and the process is typically straightforward and quick.

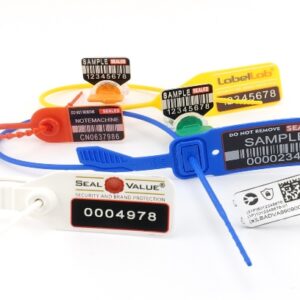

- Variety of Sizes and Colors: Available in various widths, thicknesses, and colors to suit different applications and preferences. The choice of colors can also help in color-coding and organizing different types of packages.

Applications:

- Logistics and Shipping: Used to secure and stabilize packages during shipping and transport. PP straps help to prevent contents from shifting and protect items from damage.

- Packaging and Bundling: Applied in packaging operations to bundle products together, such as in palletizing, and to provide additional support and stability.

- Industrial Use: Employed in industrial settings for strapping components, materials, and finished products. The strength and durability of PP straps make them suitable for handling heavy loads.

- Retail and Wholesale: Used for bundling products in retail and wholesale environments. PP straps are commonly used to group items together for display or sale.

Benefits:

- Strong and Reliable: Provides a secure and reliable method for strapping and bundling, ensuring that packages and materials remain stable and intact.

- Cost-Effective: Offers a budget-friendly solution for various strapping needs, with competitive pricing compared to alternative materials.

- Versatile: Suitable for a wide range of applications, from logistics and packaging to industrial use.

- Easy to Use: Lightweight and easy to handle, with straightforward application processes that improve efficiency.

Reviews

There are no reviews yet.