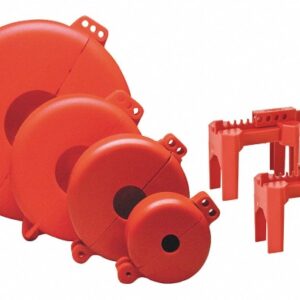

A universal lockout valve is a versatile safety device designed to secure various types of valves, including ball, gate, plug, and butterfly valves. It is engineered to prevent unauthorized or accidental operation of valves in fluid control systems during maintenance, repair, or service. The universal lockout valve ensures that valves remain in the desired position, either open or closed, by providing a secure locking mechanism that can accommodate multiple valve types.

Key Features:

- Versatile Compatibility: Designed to fit a wide range of valve types and sizes. The universal lockout valve features adjustable or adaptable components that make it suitable for use with different valve configurations, including ball, gate, plug, and butterfly valves.

- Durable Construction: Made from high-quality materials such as heavy-duty plastic or metal, the universal lockout valve is built to withstand harsh conditions and resist chemicals, extreme temperatures, and physical wear.

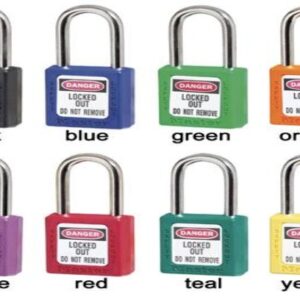

- Secure Locking Mechanism: Equipped with a robust locking system that can accommodate one or more padlocks or combination locks. This ensures that the valve cannot be operated until all locks are removed, preventing unauthorized or accidental reactivation.

- Easy Installation and Removal: Designed for straightforward application, the universal lockout valve can be quickly and easily installed or removed without the need for special tools. This user-friendly design allows for efficient use in various work environments.

- Tagging Capability: Includes a tagging area or slots where safety tags or labels can be attached. This provides clear communication about the lockout status, including details about who applied the lockout and the reason for it.

- Tamper-Evident Design: Features tamper-evident seals or visible lock slots to help prevent unauthorized removal or tampering, ensuring compliance with lockout/tagout (LOTO) procedures.

- Compliance with Safety Standards: Meets or exceeds OSHA and other relevant safety regulations, ensuring that the lockout/tagout procedures are properly followed and that the workplace remains compliant with safety standards.

Applications:

- Industrial Facilities: Used in manufacturing plants, chemical processing facilities, and other industrial settings to lock out various types of valves during maintenance or repair work, preventing accidental changes or hazardous releases.

- Commercial Buildings: Applied to plumbing and HVAC systems in commercial settings to ensure that valves remain securely in place during servicing or upgrades.

- Utilities and Infrastructure: Utilized in water treatment plants, power plants, and other utility environments to manage and control the flow of fluids safely during maintenance activities.

Benefits:

- Enhanced Safety: Provides a secure method for locking out multiple types of valves, reducing the risk of accidental or unauthorized valve operation and ensuring worker safety.

- Versatile and Reliable: Suitable for a wide range of valve types and sizes, making it a flexible and dependable choice for various applications.

- Facilitates Compliance: Supports adherence to lockout/tagout regulations and safety standards, contributing to a safer work environment.

Reviews

There are no reviews yet.