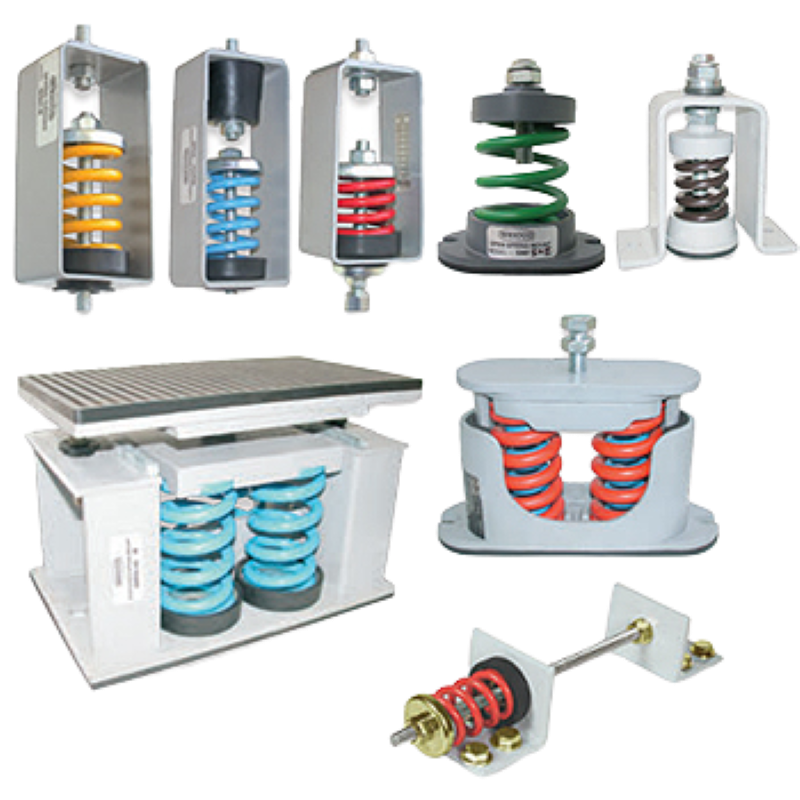

Vibration Isolators – Precision Damping for Industrial Equipment

At Anchor Building Materials Trading LLC, our high-performance vibration isolators are engineered to minimize noise, absorb shock, and protect sensitive equipment from mechanical stress. Designed for use in HVAC systems, compressors, pumps, and heavy machinery, these isolators ensure smoother operation and extended equipment life.

✅ Key Features

- Rubber, neoprene, and spring-based isolators for varied load capacities

- Threaded stud, bolt-down, and sandwich mount designs

- Corrosion-resistant metal components for harsh environments

- Load ratings from 5 kg to 5,000 kg

- Ideal for floor-mounted, wall-mounted, and suspended systems

🏭 Applications

Used across industrial plants, commercial buildings, and marine installations, our vibration isolators reduce structure-borne noise and mechanical wear—enhancing system efficiency and operator comfort.

Reviews

There are no reviews yet.